Xantia Height Corrector Overhaul: Page 3

-

Generally, reassembly is a straightforward reversal of the disassembly. It is vital that the shuttle valve and extension lever is in absolute correct alignment as otherwise it will not fit back into the cradle properly. This picture shows the correct aligmnet of the extension lever relative to the body. Note that thin the picture it does not look quite square and in fact the side of the extension lever MUST be absolutely parallel to the hydraulic ports. There is a convenient nick (identified by the arrow in the picture) that must be exactly in line with the valve body fixing holes.

Alignment of the Extension lever

-

Lubricate the diaphragms with a little LHM before resassembly and wipe LHM across the diaphragm sealing surfaces on the body.Ensure that the body and all componets is scrupulously clean and free of every trace of dirt.

-

Begin reassembly by lubricating the shuttle valve very copiously with LHM and dripping some LHM into the suttle valve bore in the valve body. Slide the valve back in and carefully ease the edge of the diaphragm over the lips of the valve body sealing surface. Check very carefully that it is correctly aligned and ease on one of the diaphragm sealing rings, again being very careful not to distort it. Use finger/thumb pressure only and press it on evenly.

-

Replace the dust cap on the extension lever end and gently support the valve in a vice.

-

Begin rebuilding the other end, starting with the baffle...

Replacing the baffle

-

Followed by the circlip...

Replacing the circlip

-

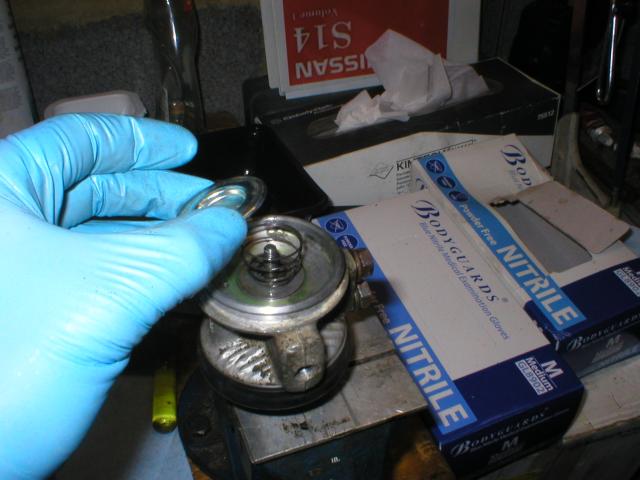

And the spring. Note the orientation of the spring and plate...

Replacing the spring and plate

-

Replace the diaphragm, the top plate,the nut and the diaphragm sealing ring. Finally replace the dust cap. Overhaul and reassembly is now complete.

-

Repace the valve back onto the height corrector mechanism crade but not before giving the cradele mechanism a good clean, checking that both turrets move freely and easily. Grease the springs and turrets. Do not overtighten the hydraulic unions and check for leaks once the car is running again. Height corrections should now be satisfyingly rapid and sensitive.

This is the last page. All the difficult work is now done and this page deals with the reassembly of the valve.