Peugeot 206 1.4 Cambelt Replacement: Page 3

Lubricate the O ring with a little vaseline and slip ity onto the pump, ensuring it sits right at the bottom, against the flange. Clean the aperture in the block and install the new water pump, ensuring it goes in easily and sits fully square. Replace the two bolts, ensuring the 13mm standoff bolt goes at the top. Tighten the bolts only moderately and evenly, otherwise there is a risk of distorting the pump body and risking leaks.

-

Install the new cambelt eccentric tensioner and do the 13mm retaining nut up so that the tensionr can still easily move.

-

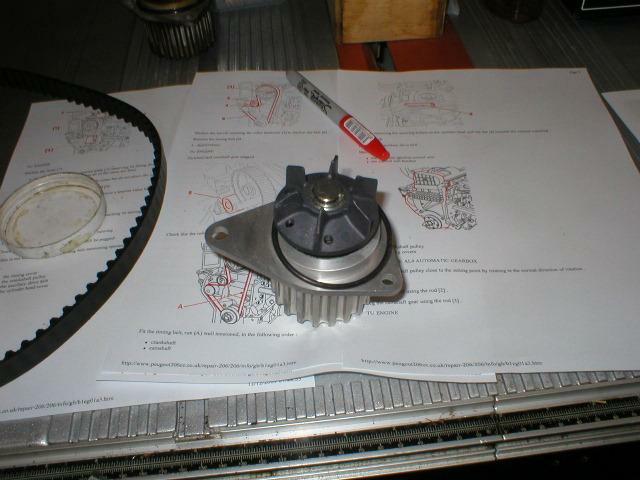

Install the new cambelt, taking care not to spill any oil on it and observing any directional arrows on it (the engine runs clockwise). Start at the crankshaft sprocket and ensure the front run of the belt between the crank and cam sprockets is pulled very tightly otherwise your timing will end up a tooth out. I find it best to enage the teeth into the crank sprocket and then pull the belt tightly up to the cam sprocket and engage the teeth around the cam sprocket before fitting the belt to the tensioner and water pump. The belt should end up looking like the picture below.

Tensioner Adjusting Tool

-

The picture shows a tool engaged in the 1/4" square hole in the tensioner. That's my home-made tool but a 1/4" socket set "T" bar works well.

-

Adjust the initial tension by moving the eccentric tensioner around until the tension in the belt is such that it can be just twisted through 90 degrees using finger and thumb. Do not tension it too tightly.If using the electronic tension gauge, tension to 44 SEEM Units.

-

Now remove the camshaft and crankshaft locking pins and rotate the engine cliockwise through six revolutions using a socket on the crankshaft bolt. NEVER rotate backwards. Recheck the timing by reinserting the locking pins in the crankshaft and camshaft sprocket as described earlier.

-

Remove the locking pins and recheck the cambelt tension, again ensuring the belt can be just twisted through 90 degrees on its longest (front) run using only moderate finger/thumb pressure. If using the gauge, reset to 44 SEEM Units. Ensure if adjusting manually that the belt is neither too loose nor too tight, bearing in mid the whiole engine expands when hot and tensions the belt a little more. When content, torque the tensioner 13,mm nut to 20 N/m.

-

If using a SEEM gauge, the measureing head should be fitted as shown.

SEEM Gauge Head